Background

Energy management is becoming a growing component of business strategy, as industrial companies from factories to energy utility field sites are looking more closely at their energy profiles in order to identify opportunities for increased productivity, manage energy usage, decarbonization, and cost reduction.

A facility or field site needs to measure and monitor their equipment to track and report improvements, reduce carbon emissions caused by auxiliary resources and energy consumption, operate more efficiently, manage energy costs, as well as check and repair equipment as needed. They are increasingly adopting energy monitoring technologies and considering onsite resources, including cloud, artificial intelligence (AI), and the Internet of things (IoT) to bring widespread connectivity for everything from machines in production lines, to heating and cooling systems, to office and factory lighting.

Requirements

Industrial companies aim to achieve complete operation visibility with automated, continuous data from infrastructure and assets at every point of the supply chain or field site. A leading global integrator required a secure and reliable platform for smart energy management, specifically for energy utility sites. The resulting joint effort incorporates Lanner’s industrial-grade hardware with the following requirements.

- Multiple Connectivity Configurations

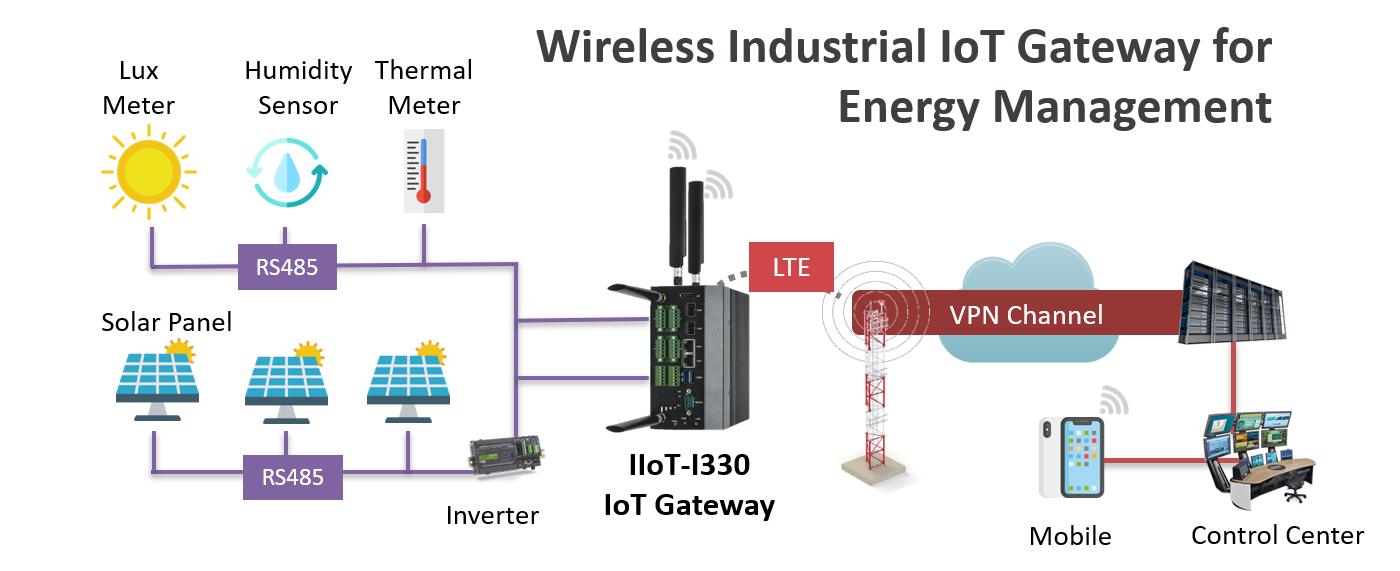

Robust connectivity plays a critical role in the collection and delivery of data generated from the sensors. Various LAN port features, including GbE LAN and SFP fiber, serial port connectivity, and wireless connectivity to communicate with PLC, RTU, HMI, and/or SCADA and control center. The ideal gateway would always also provide a cellular backup option to always stay connected. In addition to advanced LAN bypass for fault-tolerant LAN traffic to ensure operations network resiliency. - High Performance and Scalability

The platform requires a high-performance, low-power consumption multi-core processor for high-performance computing data and consolidating multiple workloads. The platform should also support additional storage expansion, as demands increase, for flexible scalability. - Wide Operating Temperature Range

Given the possible extreme temperatures in an energy utility site environment, the appliance must be able to operate at a wide temperature range without sacrificing operation safety and productivity. Extreme temperature ranges from -40~70°C are essential, and an advanced passive cooling system ensures reliable operating performance. - Multiple Front Access I/O Features

The platform system requires multiple I/O connectivity for IoT sensors and relays, including COM ports, DI/DO. - Robust Security

An on-board TPM for secure crypto-processing and tamper resistance at the hardware level, to protect data communications.

Solution

Robust and secure connectivity is essential for the assets to be managed, optimized, and maintained through data analytics and insights.

Lanner’s IIoT-I330 is a fanless industrial gateway, powered by quad-core Intel® Atom for optimized performance and power consumption and optional LTE/Wi-Fi 6 wireless connectivity, with a wide operating temperature range, a robust, secure, and reliable hardware solution for industrial applications.

IIoT-I330 features flexible I/O connectivity, including multiple RS485 ports, DI/DO ports, and console port, in addition to multiple GbE RJ45 ports, SFP ports, and USB 3.0 ports to offer high density, for various industrial IoT application needs.