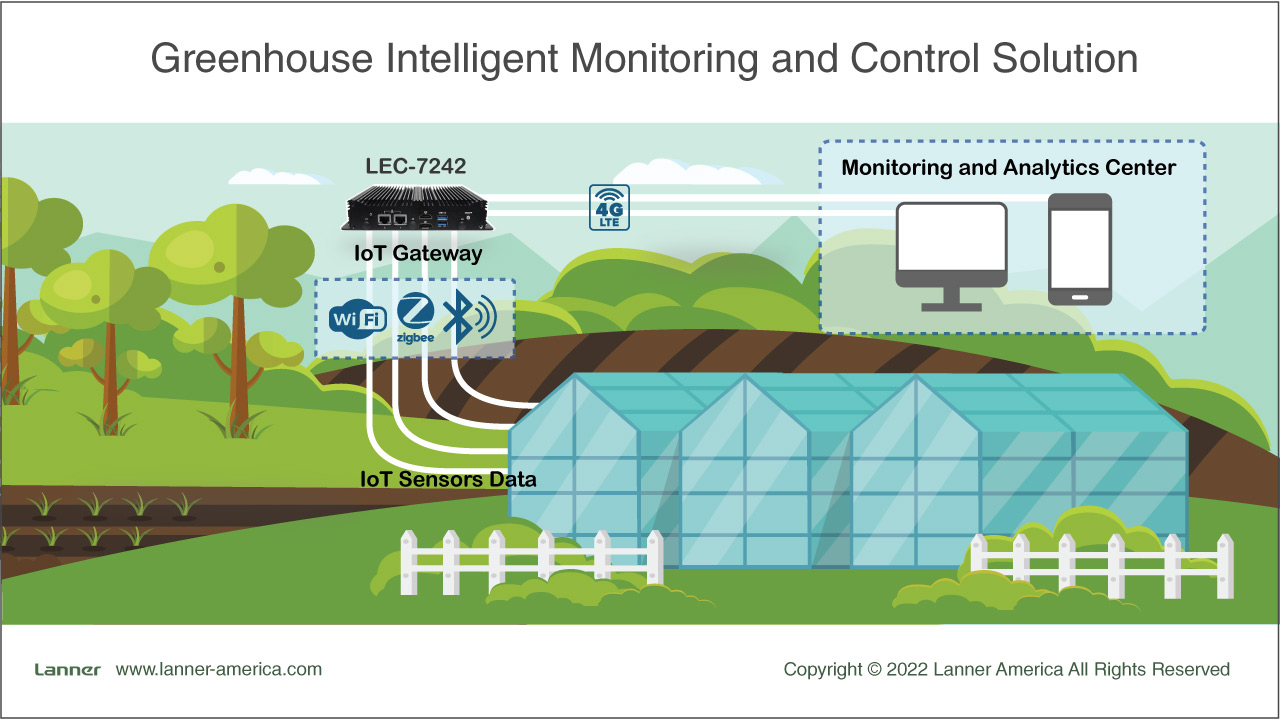

An IoT-based intelligent greenhouse monitoring and control solution solves these challenges, as it allows the greenhouse staff to remotely monitor and automatically control the microclimate of the entire greenhouse. The solution depends on IoT sensors, actuators, intelligent IoT gateway such as LEC-7242, and a cloud-based remote monitoring center.

Greenhouse Monitoring and Controlling Challenges

Greenhouses are built especially for protecting delicate or out-of-season plants from hostile climates such as excessive cold, heat, or wind. Although greenhouse technology has evolved from the simple window refuge to the controlled environment tailor-built for specific plants, it can still be challenging to monitor and control them.

Creating and controlling microclimates inside greenhouses can be difficult, especially for delicate crops that require high precision, such as orchids, exotic fruits, or mushrooms. Precision farming requires exact temperature, humidity, ph, moisture, and lighting levels so that these delicate plants can thrive and yield.

But still, even though greenhouses are built with actuators such as motors and fans to open windows to let the airflows in, ventilate, or move shades to cover up excessive sunlight heat, greenhouse workers have to manually start such actuators. Modern greenhouse environmental control systems use Programmable Logical Controllers (PLCs) and SCADA to introduce a level of automation and control.

Although such systems can help monitor and control greenhouses more precisely, they don't come without challenges. For instance, PLCs have poor data exchange mechanisms, are not interoperable with other systems, and are not easy to scale.

The Greenhouse Intelligent Monitoring and Control Solution

An IoT intelligent greenhouse monitoring and control solution provides a way to remotely and automatically take care of the crop within the greenhouse. The solution uses climate, irrigation, nutrient application, temperature, humidity, and lighting control systems to ensure that the crop remains healthy and at the highest quality.

The vital elements of the Greenhouse intelligent monitoring and control solution.

A. Sources of data.

The intelligent greenhouse solution uses internal IoT sensors or meters to collect Ph, moisture, humidity, temperature, photometric, electrochemical, water, energy, CO2, and photosynthesis data. The solution may also use external environmental IoT sensors that measure sunlight, wind direction, and temperature. Other sources of data may also come from external weather data feeds. The solution is also composed of actuators that can influence a shift in the internal microclimate by opening and closing irrigation, fans, shade net, liquids flow control, or heating/cooling.

B. The IoT Gateway.

An IoT gateway integrates all IoT sensors data, pre-processes it, and provides communications to a cloud-based monitoring system. An intelligent IoT gateway offers capabilities such as pre-processing all IoT-gathered data (compression, deduplication, encryption, redundancy elimination, and more) to optimize data storage and lower network delays. An IoT gateway also provides rich I/O to connect sensors, meters, displays, PoE-powered devices, and external drives. Other vital components of a greenhouse IoT gateway is its support for robust wireless communications and its robust design to withstand the environmental-difficult conditions for IT equipment in greenhouse deployments.

The Industrial IoT Gateway: LEC-7242

The greenhouse IoT sensors are interconnected via WiFi or LTE to Lanner's Industrial IoT gateway, LEC-7242. The LEC-7242 is an Industrial wireless gateway powered by Intel® Apollo Lake CPU and certified by FCC/CE/PTCRB for LTE or WiFi. The appliance is designed for IoT/IIoT edge and wireless security. The device is built using advanced fanless passive cooling technology so, it can operate in a wide range of temperatures 0°C~50°C / -20°C~70°C, and relative humidity of 5%~95% (Non-condensing) environments—a perfect fit for greenhouses.

C. Cloud monitoring.

A third vital component for the Greenhouse intelligent monitoring and control solution is the remote monitoring and control platform. The IoT gateway sends all pre-processed IoT data to a remote server (local or cloud) for further monitoring, control, or analysis. The greenhouse staff can remotely monitor and control vital data regarding the crops at any time and from any device.

Benefits

a.Real-time Monitoring and Control system.

The intelligent monitoring and control solution helps the greenhouse staff closely watch every metric inside and outside the greenhouse. It provides the greenhouse team with access to real-time updates and reactive/proactive alerts for humidity, ph, luminosity, temperature levels, anywhere and anytime. The greenhouse staff can take the necessary immediate actions such as turning off/on fans, lights, vents, or pumps remotely using a mobile device and avoid disasters.

b.Optimize production while saving on water and energy.

The greenhouse staff can use the data collected by the intelligent monitoring and control solution to analyze the current energy and water consumption and make informed decisions. With this analysis, the greenhouse staff can control irrigation and lighting to match the local external conditions. This control can help reduce irrigation by considering humidity levels or increasing irrigation by analyzing temperature. In addition, the greenhouse staff can also enhance production by assessing the climatic variations, plant-centric lighting, and local soil and adapting it accordingly.

c.Advanced greenhouse applications with AI and ML.

The rich and vast data collected by the IoT sensors and devices and the edge computing capabilities of an IoT gateway such as LEC-7242 allow advanced applications from technologies such as Artificial Intelligence (AI), Machine Vision (MV), and Machine Learning (ML). The intelligent solution leveraging such technologies can create the ideal greenhouse automation system and enable precision farming. The system could also be used for microclimate prediction, power and water consumption analysis, and even control of carbon dioxide.

d.Analyze and Predict Crops.

Use data analytics to keep aware of plant essentials such as soil nutrients over the long term and predict the plant's production output using predictive monitoring techniques. With Machine Learning (ML) algorithms at a high-end server or cloud service, greenhouse staff will know the required energy and water that the plant will require, plus they may also predict the harvesting date. In addition, the greenhouse team will be able to track the plant's productivity throughout the year and identify and protect plants from diseases before crops are destroyed.

Next Steps.

For more information on the intelligent IoT gateway or the greenhouse monitoring and control solution, please contact Lanner’s sales representative.

Related Articles

- Climate Control and Monitoring Systems in Commercial Greenhouses

- Greenhouse Automation for In-door Farming