Power and Energy

Cybersecurity holds critical significance for substations, given their integral role in the electrical grid as key nodes for electricity distribution to various sectors including residential areas, commercial establishments, and vital services. A breach in substation cybersecurity can lead to not just interruptions in the power supply, but also carry substantial safety hazards. This includes possible physical damages which might pose risks to both the workforce and the public.

Read more: IEC61850-3 Certified Computers Enable Cybersecurity in Automated Substations

Energy management is becoming a growing component of business strategy, as industrial companies from factories to energy utility field sites are looking more closely at their energy profiles in order to identify opportunities for increased productivity, manage energy usage, decarbonization, and cost reduction.

Read more: Wireless Industrial IoT Gateway for Smart Energy Management

With the growth in industrialization and electricity access across the globe, electrical power consumption continues to grow at a rapid pace and therefore, it becomes very important to efficiently and skillfully manage power distribution and consumption. Automation in the power sector has become a requirement as it enables smart grids that can control and monitor power to minimize losses, improve reliability and productivity, manage demand cost-effectively and enable future-capacity planning.

Read more: Critical Infrastructure Resilience System Facilitates Interconnected Utility Networks

The world has an energy problem as fossil fuels are running out and it is necessary to transition from fossil fuel dependence to renewable and clean energy, creating a cleaner and greener world. The energy and utility industry, from the utility of water, district heating, or power, has many challenges ahead.

Read more: Low-power IoT Gateway Promotes Sustainable Clean Energy Efficiency

Growing urbanization rising energy demand and increasing costs have further motivated the power sector to utilize their electrical system capabilities more efficiently and smartly – toward smart substation transformation. The three main challenges of grid modernization are climate change driving extreme weather events impacting electrical grid changes, increased risk of cyberattacks on grid infrastructure, and high penetration of renewable energy sources which increases power flow complexities.

Read more: Virtual Protection Relay for Power Grid Modernization

With technological advances in Internet of things (IoT) and big data analytics, digital information technology (IT) systems are rapidly integrating with operational technology (OT) systems, merging business processes, insights and controls into a single uniform environment, to accelerate improving productivity, streamlining workflows, and increasing bottom lines for industries including manufacturing, utility, transportation, communications, medical and retail.

Read more: Securing Critical Infrastructure with Rugged Cybersecurity Appliance

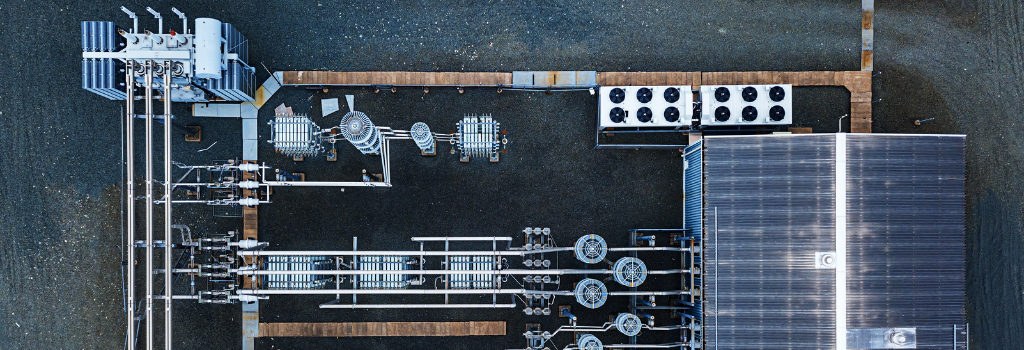

Substations are the hearts of the power grid, enabling the complex process of transmission and distribution of electricity. Increasing new loads and maintaining system reliability while reducing machinery and labor costs is a continuous challenge for substation managers. A digital substation can help reduce costs, increase system reliability, and even integrate into eco-friendly power initiatives.

Read more: Scalable Rugged Computer Enables Intelligent Digital Substation