Industrial Automation

AI-powered machine vision inspection is crucial for smart factories to ensure efficient production processes and maintain high product quality, as modern factories generate vast amounts of visual data from sensors and cameras deployed throughout the production floor. Transmitting this data to a centralized cloud for AI training and inferencing can strain network bandwidth, lead to delays, and raise concerns about data security.

더 읽기: Enabling edge AI inferencing and training for Factory Machine Vision

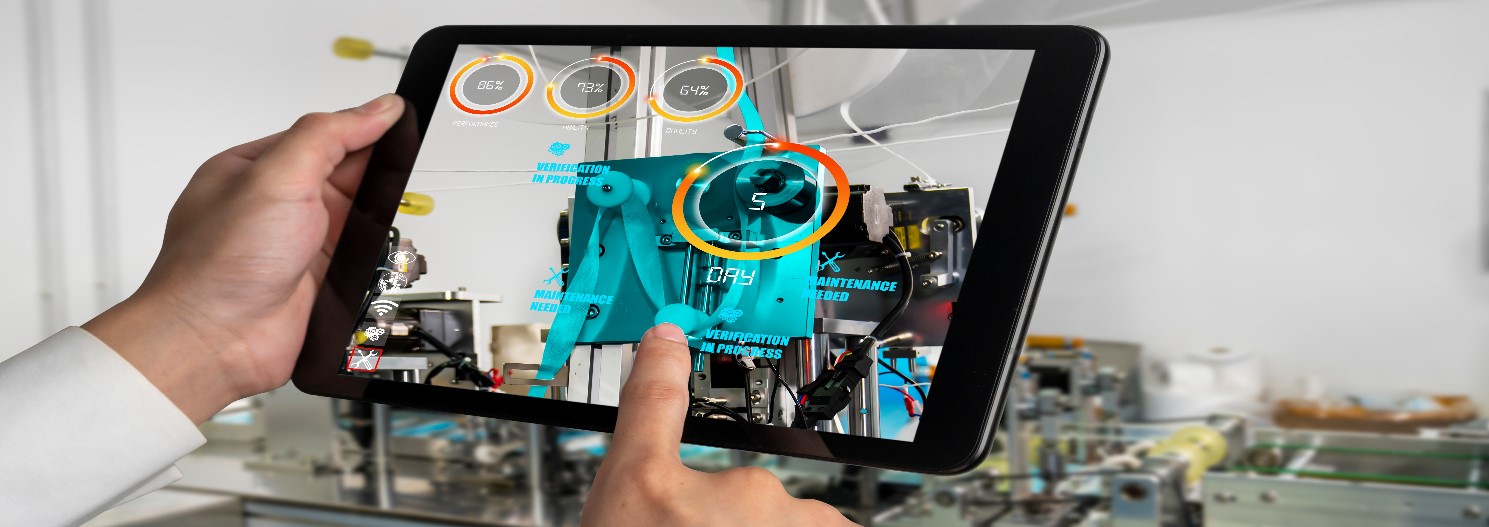

In modern manufacturing, quality control is crucial for product excellence and cost reduction. Traditional methods encounter efficiency and adaptability challenges. Portable AI vision systems, fueled by edge AI computing and advanced computer vision, provide a streamlined and accurate solution, optimizing inspections in diverse industries.

더 읽기: Optimizing Inspection Processes with Portable AI Vision Solutions

The AI-based industrial visual inspection system is a revolutionary solution that combines the power of artificial intelligence and computer vision to enhance the accuracy and efficiency of visual inspections in industrial settings.

A well-established leader in the foods and beverages industry was in search of an AI-powered industrial automation edge computing solution that could be relied upon for managing their wide range of foods and beverages products; with a growing customer base and increasing product demand, this company decided that streamlining the distribution process and optimizing operational efficiency were of the upmost importance if they were to meet market expectations.

더 읽기: Enabling A Robust And Efficient Distribution Process Using Lanner’s Edge AI Server Appliance

One of the biggest challenges facing today’s textile industry is the fact that it for the most part still relies on human vision and manual inspection for defect detection, meaning the industry not only operates on thin margins but also has a considerably high defect rate.

더 읽기: EAI-I130: Bringing AI And Machine Learning To The Next-gen Textile Production

A few extensive warehouse facilities are already using some sort of automation, especially Autonomous Mobile Robots (AMRs), to help them stay ahead in their industry. But AMRs don’t come without challenges, especially when deploying them indoors in closed spaces. AMRs need to respond in real-time; they need to be able to make decisions on the go.

더 읽기: AMRs with Embedded GPU Computing Bring Logistics 4.0 Benefits to Large Scale Warehouses

Autonomous lawn mowers are designed to reduce lawn maintenance labor costs and time. But an inefficient or improperly programmed or operated robotic lawn mower would defeat the whole purpose of “autonomy.” An unproductive and unsafe robot will turn a gardener into a programmer, taking away the focus on what matters: the grass.

더 읽기: Highly Efficient Edge AI for Commercial Autonomous Mowing