Background

Since cell tower sites and multi-site offices are spread over multiple geographies, covering urban and remote areas, monitoring cell tower sites from a centralized location is becoming increasingly difficult. Non-visibility of energy consumption and asset maintenance further increases OPEX and significant security threats.

Remote monitoring of cell sites can significantly assist telecom network operators in driving down energy usage and extending infrastructure lifespan. Organizations are now looking to IIoT with edge computing as a solution. Moving away from cumbersome, multi-domain monitoring, a cell tower monitoring system allows for a unified, aggregated end-to-end wireless monitoring, over cellular or fiber networks, from 4G LTE, 5G, CBRS, or other networks for intelligent monitoring.

Leveraging remote monitoring technology allows for monitoring cell sites 24/7, remotely controlling power resources and optimizing energy consumption, monitoring asset health and performing predictive maintenance, and enhancing site security with reporting of intrusions and hazards to minimize downtime. Efficient management of cell tower sites can have a direct impact on reliability, reduce costs, improve customer service, and expand the customer base.

Requirements

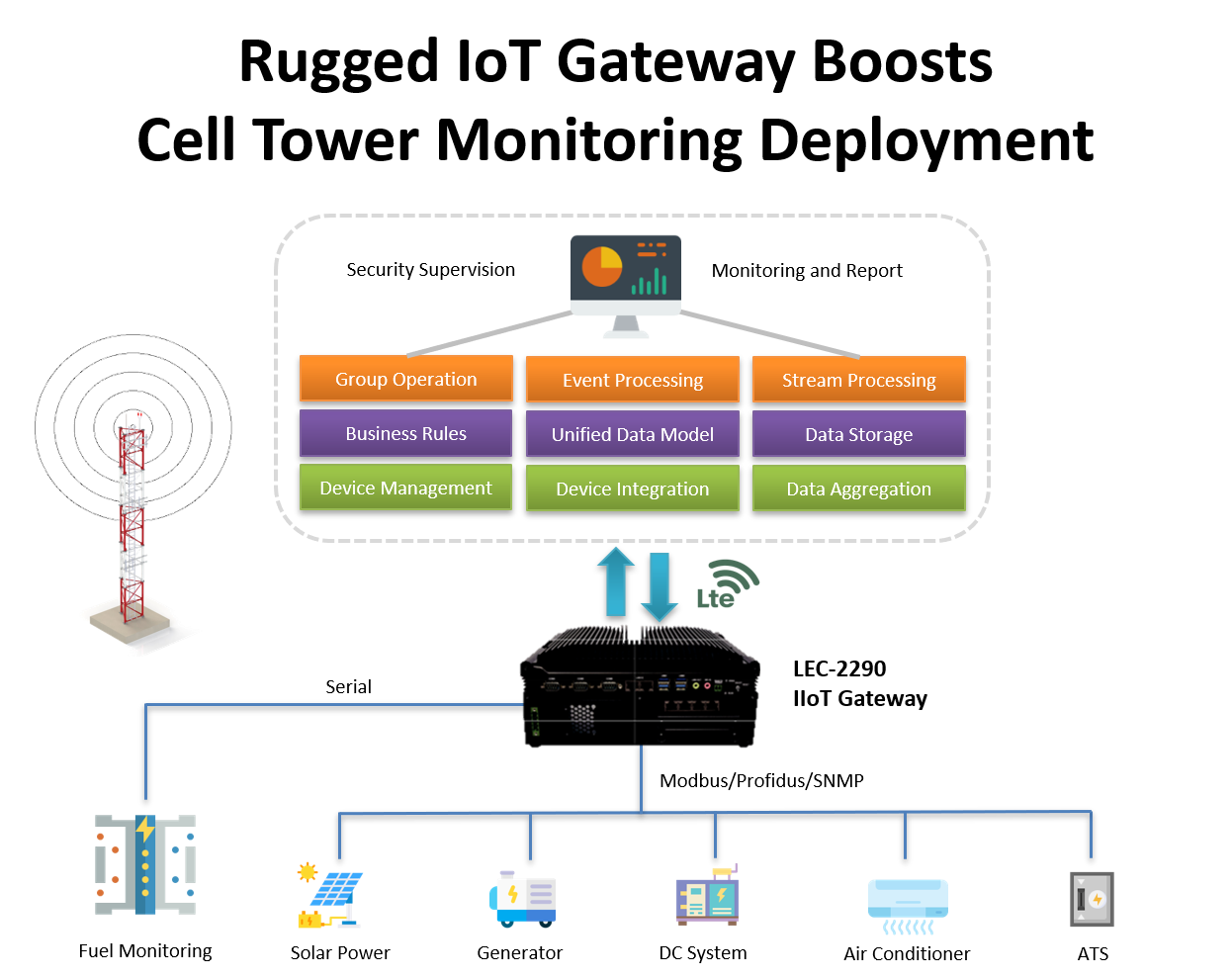

A smart cell tower monitoring solution combines artificial intelligence, machine learning, and edge computing with sensors and connected devices to monitor and control various scenarios including access control, generator fuel leaks, energy consumption monitoring, and infrastructure maintenance.

Lanner cooperated with a system integrator to offer a cell tower monitoring solution to an oil company in the Middle East. The IIoT gateway needed to meet the following requirements for the solution:

- Multiple Gigabit Ethernet ports – The system needs to support 4x GbE RJ45 and 4x GbE SFP ports. The Gigabit Ethernet connects several systems and sensors for remote monitoring.

- LTE for EMEA bands with integrated GPS - The LTE modules have exceptionally small footprints, and can optionally be appointed with multi-receiver GNSS capability for satellite positioning.

- Various I/O connectivity for sensors, alarm, meters, and PLC – RS-232/485, DI/DO ports for hybrid & fuel monitoring.

- Rugged and Fanless Design – the gateway is also designed to work in challenging environments, such as those found in large-scale cell sites. The gateway appliance comes in a fanless design and can operate across wide -20°C To 55°C temperatures.

Solutions

The challenges of monitoring cell tower sites from a centralized location are evolving, and a remote cell tower management solution can ensure security, energy efficiency, and maintenance. Implementing AI-based industrial automation at the edge is crucial in mission-critical applications and requires real-time data processing with low-latency response.

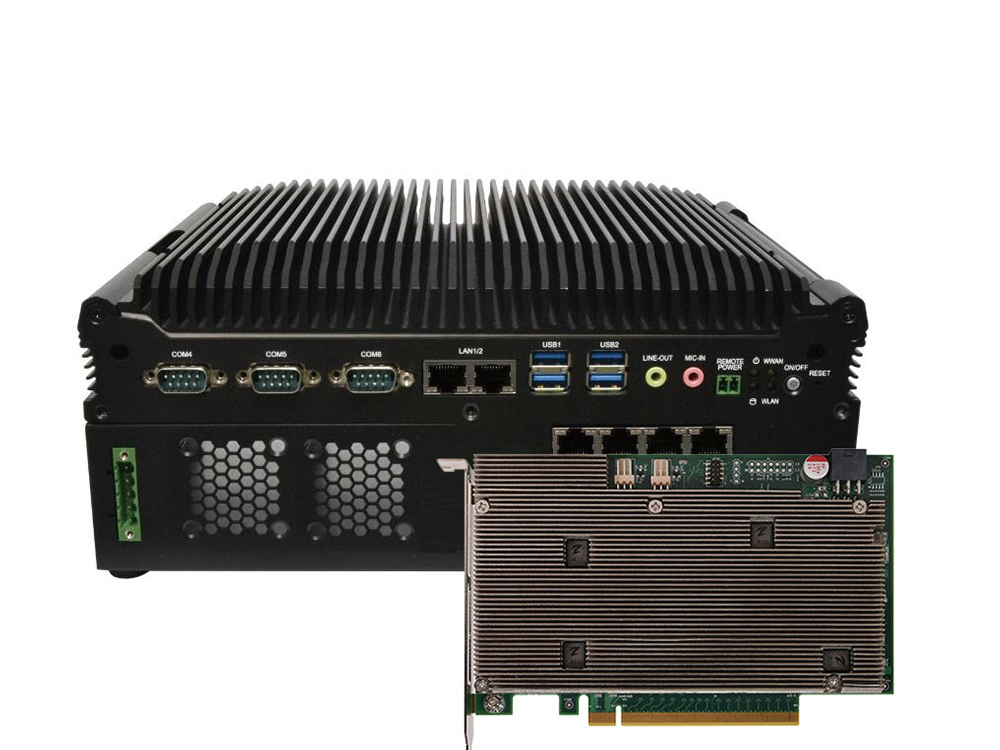

Lanner’s LEC-2290 has the computational performance to deliver real-time AI inference with scalable expansion at the edge. The LEC-2290, an intelligent edge computing box PC, comes with support for Intel® Core™ i7-8700T/i7-8700 CPU (codenamed Coffee Lake S). This IPC features 2x DDR4 2133/2400 SO-DIMM (Max. 32GB), 2x RJ45 GbE LAN, 4x PoE, 4x USB3.0, 6x COM ports, 8x DI & 8x DO, 2x removable HDD/SSD external slots w/ RAID, 1x mSATA, 1x PCIe*16, 1x PCIe*4, 1x Mini-PCIe w/ Nano-SIM and 1x B Key M.2 w/ Nano-SIM.

For 4G LTE remote monitoring, the PGN-300 swappable caddy design makes system maintenance easier in the field and upgrades to meet the local wireless frequency bands for 24/7 uninterrupted operations. Lanner’s Industrial Grade PCIe Expansion Network Interface Card LEK-IS401 comprises four GbE SFP ports and is driven by the powerful Intel i210IS Ethernet controller. This industrial-grade expansion card supports operating temperatures of -40 to 70ºC for demanding rugged environments.