The AI-based industrial visual inspection system is a revolutionary solution that combines the power of artificial intelligence and computer vision to enhance the accuracy and efficiency of visual inspections in industrial settings.

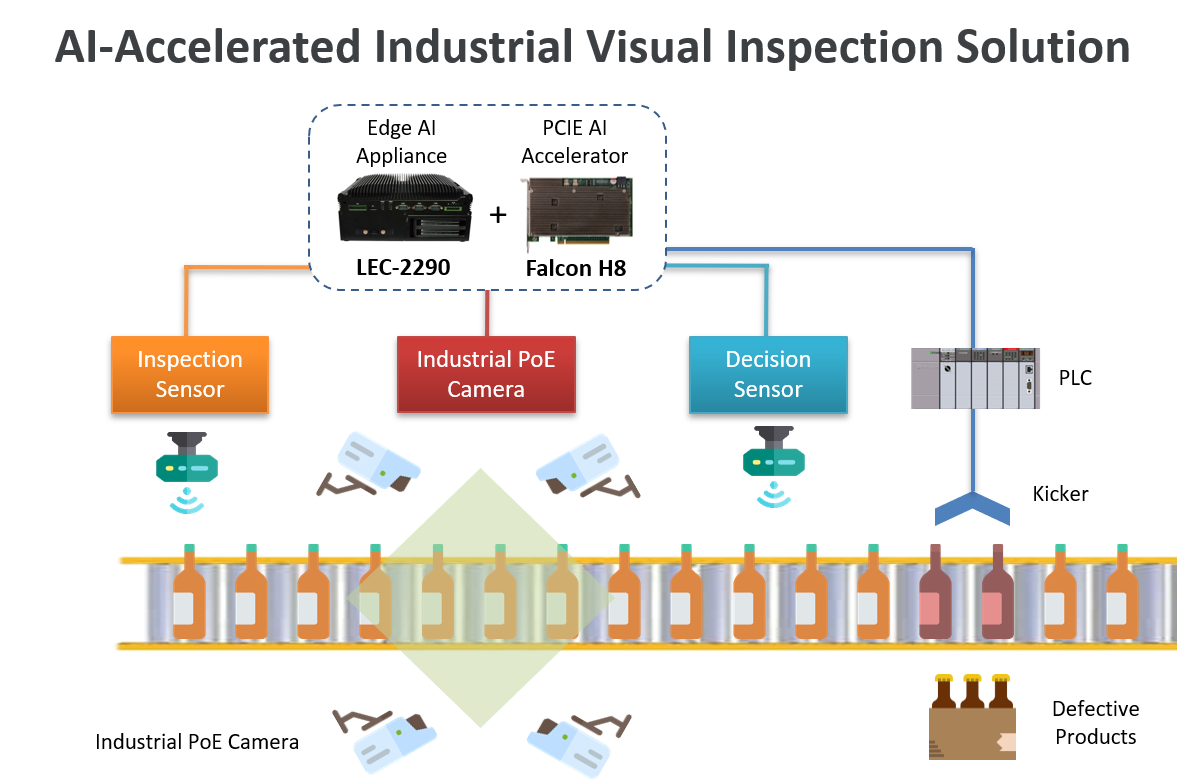

This system uses Lanner's Edge AI appliance LEC-2290H powered by the high-performance and cost-efficient PCIe AI accelerator card Falcon-H8. The solution can run advanced algorithms to analyze images and identify defects or inconsistencies automatically, reducing the need for human inspection while ensuring the highest quality control standards. With its ability to detect and flag issues in real time, Lanner's AI-based inspection system can help companies improve productivity, reduce costs, and ensure the safety and compliance of their operations.

Challenges

Making a robot with video cameras imitate a human visual inspector's capabilities is no easy task. Overall, automating industrial visual inspection can be a complex and challenging process. But still, it can also offer significant benefits, such as increased accuracy and consistency, higher inspection speeds, and reduced labor costs.

Below are some of the most common challenges when trying to automate industrial visual inspection:

- Complexity:

Industrial products can be complex and may have different features that need to be inspected. This can make it challenging to design an automated inspection system that can accurately and consistently detect all relevant defects. - Variability:

Industrial products may vary in size, shape, color, and other characteristics, which can make it challenging to develop an automated inspection system that can handle this variability. - Lighting:

Industrial inspection often requires examining products under various lighting conditions, which can be challenging to replicate in an automated system. - Lack of specialized inspection equipment and software:

Automating industrial visual inspection can be expensive, requiring developing and deploying specialized in-house inspection equipment and software. Optimized appliances for running industrial AI are costly and hard to find. - Integration with other systems:

Automating industrial visual inspection may require integration with other manufacturing systems, such as quality management systems or enterprise resource planning systems, which can be complex and time-consuming.

Solution

Automating industrial visual inspection typically involves using computer vision and machine learning techniques to analyze images or videos of industrial equipment or products to detect defects or variations in the manufacturing process.

There are various steps and components that may be involved in automating industrial visual inspection; these include data collection, image or video processing, and machine learning models. After these steps have been accomplished (the machine learning model has been trained), the system would need to be deployed in the industrial environment. Deploying an automatic industrial visual inspection may require integrating the model into an existing industrial control system or building a custom system specifically for visual inspection.

The Edge AI Image Processing Hardware

An Edge AI appliance is a device or system designed to perform AI computations at the edge of a network rather than relying on a centralized data center or cloud server. This means that the device can process and analyze data locally, in real time, with minimal latency. The device is typically small, portable, and power-efficient, making it well-suited for deployment in remote or difficult-to-access locations.

The Edge AI appliance can deploy different AI models and keep up with industrial environments' complexities, variabilities, and light conditions. An industrial-grade Edge AI appliance, such as LEC-2290H is an excellent fit for compute-intensive workloads such as industrial visual inspection. Plus, the capacity of this edge AI appliance can also be extended with the high-performance and cost-efficient PCIe AI accelerator card, Falcon-h8.

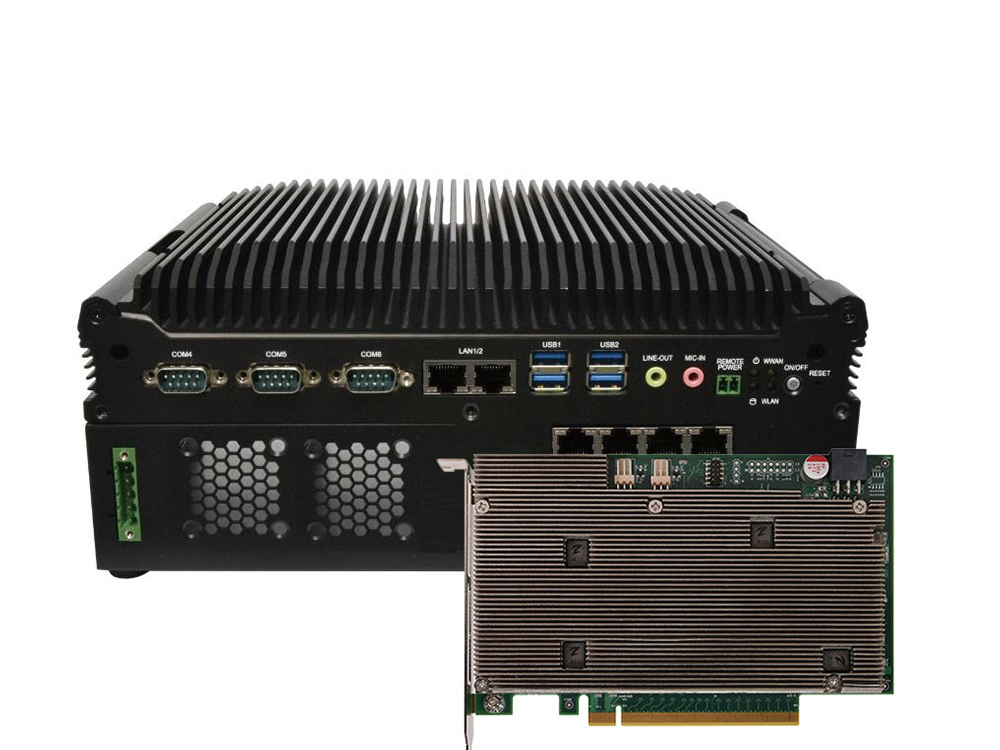

LEC-2290H Key Features:

- Industrial-grade inference box PC with Intel® Core™ i7 Processor (i7-9700TE Coffee Lake)

- It allows up to 156 TOPS AI performance with Hailo-8 Software Development Tools

- Robust wireless with 5G/LTE/WiFi 6 connectivity

- -40°C To 70°C operating temperature range

- Abundant I/O, including 2x RJ45, 4x PoE, 4x USB3.0, 6x COM, 8x DI/DO

- 2x RJ45 GbE LAN, 4x PoE, 4x USB3.0, 6x COM Ports, 8x DI & 8x DO

The best of this AI image processing hardware is its integration with Lanner's Falcon H8 modular- a PCIe form factor with an easily deployable solution for helping other appliances offload CPU loading for low-latency deep learning inference. The Falcon H8 AI accelerator card, through its standard PCIe interface, enables typical devices like Edge AI boxes, NVRs, IPCs (Industrial PCs) and robots to perform image/video intensive edge AI applications like industrial visual inspection.

The Architecture

Video cameras on an assembly line collect live video feed data and send it to an NVR or Edge AI box for data processing. The images of any product (abnormal or normal) from different production stages are sent to the central learning machine- which are hosted on-premise or remotely. This machine builds an analytical model to distinguish between what's good and what's not. The more product data is fed into this machine-learning engine, the more precise and fast the system will be.

Benefits

An autonomous visual quality inspection system uses visual intelligence to distinguish between good and bad products. It can also introduce object classification to differentiate defects in objects into different types and learn and address potential root causes. An ML system can be trained to perform classification tasks and even use robots to take actions. Using the LEC-2290H expanded with Falcon-h8 will improve the time it takes for abnormal objects to be classified.

As previously stated, implementing an AI-based industrial visual inspection system can be a complex and challenging task. However, once successfully implemented, it can drastically improve the precision, consistency, and speed of visual inspections. Automating industrial visual inspection can provide many benefits for the entire operations, such as:

- Enhanced accuracy:

Automated inspection systems can detect and identify defects with a higher precision level than human operators. - Improved consistency:

Automated inspection ensures that inspections are performed similarly across all products, reducing the potential for human error. - Increased speed:

Automated inspection can process products much faster than human operators, increasing the efficiency of the inspection process. - Greater flexibility:

Automated inspection systems can be programmed to handle different products and defects, making the inspection process more adaptable. - Reduced labor costs:

Automated inspection reduces the need for human operators, leading to lower labor costs. - Reduced manufacturing costs:

With a more accurate and faster inspection process, defects can be detected early on, which can help to avoid costly scrappage or rework, and thus will help to reduce the overall manufacturing costs - Increased safety:

Automating dangerous inspection tasks can enhance safety in the workplace. - 24/7 operation:

Automated inspection systems can operate 24/7, increasing the overall productivity of the inspection process.

Next Steps

For more information on other edge AI appliances or the industrial visual inspection solution, please contact Lanner's sales representative.