Background

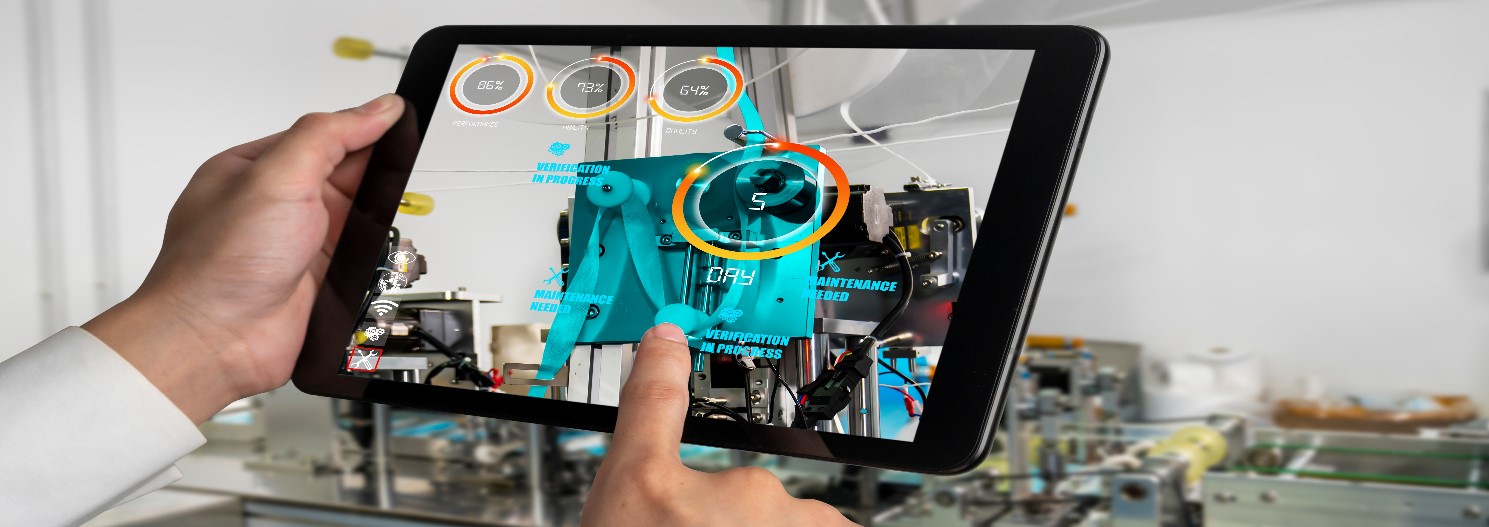

In modern manufacturing, quality control is crucial for product excellence and cost reduction. Traditional methods encounter efficiency and adaptability challenges. Portable AI vision systems, fueled by edge AI computing and advanced computer vision, provide a streamlined and accurate solution, optimizing inspections in diverse industries.

AI vision solutions provide the flexibility to be easily deployed and repositioned across various points in the manufacturing process, allowing for a more comprehensive and adaptable inspection strategy. AI vision solutions leverage machine learning algorithms to analyze vast amounts of data rapidly and accurately, enabling the identification of defects, anomalies, and potential issues in real-time.

Portable AI vision solutions automate labor-intensive inspection tasks in smart manufacturing, speeding up production and enabling continuous monitoring without extensive manual intervention. This leads to improved operational efficiency, reduced downtime, and enhanced productivity with cost-effectiveness.

Requirements

A leading software integrator required a powerful and reliable Edge AI platform for enabling portable AI vision solution in smart manufacturing. The resulting joint effort incorporates Lanner’s industrial-grade hardware with the following requirements:

- GPU Acceleration:

Deep learning models benefit significantly from GPU acceleration. The appliance must be compatible with powerful GPUs that can handle the AI inferencing tasks efficiently. - Processing Power:

The platform necessitates a high-performance, low-power consumption processor for real-time data computation at the edge. Additionally, it should support expandable storage to accommodate increasing demands, ensuring flexible scalability - Abundant I/O Interface:

The appliance necessitates a comprehensive array of I/O ports for camera connectivity, encompassing LAN ports, PoE+ LAN ports, HDMI, DI/DO, and COM ports. This facilitates the use of sophisticated AI algorithms for analyzing visual data captured by the cameras, enabling the detection of defects, anomalies, or deviations from quality standards. - Wireless Connectivity:

Robust wireless connectivity plays a critical role in the collection and delivery of generated data. Therefore, having low-latency 5G connectivity to communicate with portable AI devices, along with a cellular backup option, is important to ensure a constant connection.

Solution

Implementing a smart manufacturing factory inspection portable AI vision system can significantly enhance quality control processes. The ability to deploy intelligent, portable systems enhances adaptability, efficiency, and overall productivity, making it a critical component in the pursuit of smarter and more agile manufacturing environments.

Lanner offers a full range of AI-accelerated industrial computers that enable video analytics solutions in industrial settings. The EAI-I131 is powered by NVIDIA® Jetson Orin™ NX or Jetson Orin Nano™ system-on-modules, delivering up to 100 TOPS of AI computing performance for a wide range of AI workloads.

The device also supports LTE, 5G Sub6, and Wi-Fi wireless connectivity and provides rich connectivity options, including 2x GbE PoE, 2x COM, 2x USB, and 4x DI/DO ports. The EAI-I131 is an industrial-grade AI inference appliance specifically designed for computer vision and video analytics solutions.