Background

The growing demand for AI machine vision can be found in fast supply-chain processes, and one such application is the unloading of boxes from pallets, or depalletization.

A system integrator specializing in delivering smart solutions for supply chain management came to Lanner in search of a hardware solution that could be relied upon for automating most of the arduous tasks involved in depalleting, so that an end customer in the logistics industry can increase their productivity, throughput and also save costs.

Requirements

The requirements are as followed:

- This AI-enabled system must be capable of recognizing each box individually when a robotic arm places them on the conveyor belt or other predefined places.

- The deployment of this smart solution must result in a higher level of unloading pallets.

- This machine vision ready system should require a smaller placement area (sufficient for the size of the largest box as opposed to the whole pallet).

- This AI-powered depalletization hardware solution should also require only a smaller robot and gripper seeing as now only lighter payloads need to be handled.

- Perhaps the most important of all, this 3D vision system, built using Lanner’s hardware solution, must deliver significant cost savings.

Solution

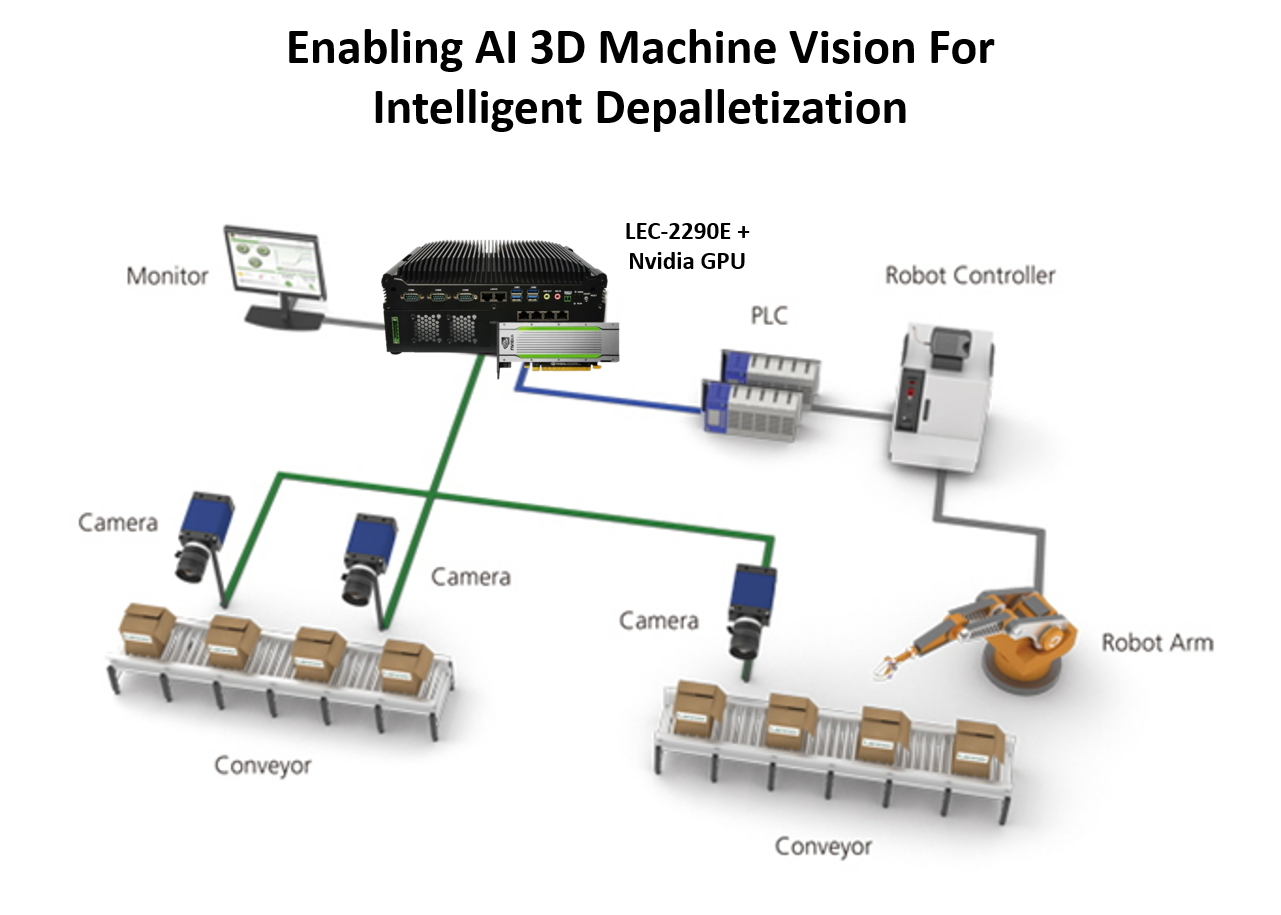

Lanner’s LEC-2290E, a GPU intelligent edge computing appliance with NVIDIA® T4 GPU support, was eventually selected as the appliance for the said AI-ready depalletization system with machine vision. The LEC-2290E, powered by the Intel® Core™ i7-8700 (Codenamed Coffee Lake S) processor, is a validated NGC-ready server for Edge computing.

When configured with NVIDIA® T4 GPUs, the LEC-2290E’s functionality, performance and ease of deployment can be trusted to have been thoroughly tested and attested for AI frameworks and virtualized, disaggregated 5G ready network architecture.

Lanner’s NGC-Ready platforms are introduced to help our customers leverage the power of an extensive range of NVIDIA GPU-accelerated software available for real-time intelligent decision making, therefore not only accelerating their hyper-converged AI-enabled application deployments at the edge but also facilitating the realization of Edge AI for an array of applications in 5G Open RAN, edge data centers, private networks and MEC.

The LEC-2290E GPU features up to 32GB DDR4 memory and generous I/O ports such as 2x RJ45 GbE LAN ports, 4x PoE ports, 4x USB3.0 ports, 6x COM ports and 8x DI & 8x DO. Its other outstanding features are as followed:

- 2x Removable HDD/SSD External Slot w/ RAID, 1x mSATA

- 1x PCIe*16, 1x PCIe*4, 1x Mini-PCIe (PCIe + USB2.0) w/Nano-SIM, 1x B Key M.2 (PCIe + USB3.0) w/ Nano-SIM

- Built-in TPM 2.0 & IPMI Support

Benefits

The combination of high-end 3D machine vision with intelligent robotics made possible with a LEC-2290E based AI-ready depalletization system enables pre-trained algorithms on a large database of boxes. The system, after having been deployed, immediately recognizes the types of boxes included in the database; when and if new boxes are placed, it is able to retrain itself on the spot. Such training and re-training take place continuously, ensuring universal and consistent identification for boxes of different shapes, sizes, or materials.

The LEC-2290E based 3D depalletization system enables powerful 3D imaging and texture analysis so that shiny, reflecting/black surfaces, varying texture, misleading patterns or pictures, unstuck tapes or tightly packed boxes do not go unrecognized, even when the boxes are not stacked in ordered patterns.

Another benefit delivered is high-resolution scanning in large volumes with superior accuracy. This is apparent when taken into consideration the following variables. First, seeing as pallets are often stacked on one another in different layers, the automated depalletization system must be able to scan the lowest and the highest ones; secondly, there needs to be enough space left for the robotic arm to manipulate the boxes; and finally the scanning volume has to be large enough to scan the pallets from a sufficient distance.

In terms of accuracy, upon having been trained on what ever numbers of types of boxes and with the availability of the 3-D machine vision, the learning algorithms provides up to 99% pick rate accuracy, gripping precision within 4 millimeters, and picking speed of more than a thousand boxes per hour, all resulting in comparative advantages in the context of ROI, decision-making process and productivity.

Last but certainly not least, the implementation of such automated depalletization solution does also lead to a significantly safer work setting. AI-based depalletization automation with 3D machine vision accuracy pretty much eliminates the risk of injuries and man-made errors, allowing for a 24/7/365 depalletization.

Results

The recipe for a successful depalletization application is the combination of high-end 3D machine vision with intelligent robotics made possible by advanced and sophisticated machine learning algorithms, and this is exactly what Lanner’s NGC-ready LEC-2290E enables in delivering.

Lanner network appliances’ NGC-ready validation helps customers across industries accelerate their hyper-converged AI-enabled application deployments at the edge, delivering the capability for leveraging the extensive range of NVIDIA GPU-accelerated software available for real-time intelligent decision making.

Related Articles

- Enabling Automated Packaging & Sorting with Machine Vision Systems

- Improving Productivity with Multi-vision Inspection Systems

- Improving Flaw Detection with Machine Vision Systems