In this solution, we propose Lanner’s edge Artificial intelligence (AI) appliance EAI-I130. This onboard industrial-grade AI inference system can empower AMRs at a large-scale warehouse by providing an AI inference system and allowing them to operate at a private 5G edge network.

AMR Requirements for Large-Scale Warehouses.

AMRs use onboard sensors, cameras, and processors to move and transport other objects around without needing guidance. To help AMRs navigate easily across large-scale warehouses and plan their routes, they can also be deployed with pre-defined maps. But one of the critical technologies for AMRs is Artificial Intelligence (AI).

With AI, not only can AMRs detect and navigate around objects with more precision, but they can also learn from experience and adjust their behavior to new inputs. For instance, AMRs-empowered with AI can learn to avoid high-traffic areas or when the warehouse is too crowded with warehouse staff to move around.

To operate efficiently in large-scale warehouses, AMRs require the following:

- AMRs need to have the correct type of onboarding computing power to leverage AI. Cloud computing has been a compelling model for AI simply because it provides on-demand, highly scalable, and access to low-cost hardware. But the AI cloud presents many challenges for an AI-based AMR, especially networking constraints; these include high latency and dependency on an Internet connection.

- AMRs and other IoT sensors generate lots of valuable data that can be useful immediately and in the long run. Moving the large amounts of valuable data generated on the AMR to an offshore server can become quite challenging. In addition, storing all this data for later processing also challenges the storage. Ideally, data generated by an on-site AMR or other sensors must be first compressed, deduplicated, and encrypted before sending it to another server.

- AMRs move out of range and work in hostile environments. AMRs operating in large-scale warehouses can benefit from an ongoing connection to the base, especially for monitoring purposes. These warehouses can be massive, so they may not provide the best wireless coverage. But still, even when an AMR goes out of range, it needs to be autonomous to navigate through.

Solution: Embedded GPU Computing

One of the best ways to solve the challenges mentioned above is to bring AI models to operate on the edge device (Edge AI). This approach reduces (and eliminates in most cases) the need for an Internet connection and cloud computing. Bringing AI to the edge also produces extra low latency results, achieving faster AI inference and supporting real-time use cases such as AMRs.

The Edge AI Appliance (EAI-I130).

Lanner's EAI-I130 is an industrial-grade AI inference system for 5G edge, powered with NVIDIA® Jetson Xavier NX/Jetson Nano. The embedded GPU computer (NVIDIA Jetson family) boasts 21 Tera Operations Per Second (TOPS) for AI performance and energy efficiency.

The EAI-I130 also supports 5G/Wifi6 for robust wireless communications to ensure fast and reliable communication to an AMR monitoring and management base. In addition, the appliance can operate in harsh environments, as it also comes with a fanless design and is compliant with the IP40 standard.

The EAI-I130 Highlights.

- Embedded GPU Computing. The EAI-I130 is powered by NVIDIA® Jetson Xavier NX, a GPU series considered by Nvidia as the world’s smallest AI supercomputers. These supercomputers bring incredibly high performance to the edge in a small form factor SOM.

- Advanced-Data Center embedded GPU. The appliance comes with a 384-core NVIDIA Volta GPU With 48 Tensor Cores. Volta GPUs are advanced accelerators designed for AI and HPC convergence.

- 21 TOPS AI performance. With a 21 TOPS AI performance, the EAI-I130 platform can run computing vision and other neural networks seamlessly on-site.

- Robust wireless support. This edge AI appliance can be expanded to support 5G and Wifi6. This wireless capability allows reliable communications to a high-end server or storage unit.

- Rugged design. The EAI-I130 is also designed to work in challenging environments, such as those found in large-scale warehouses. The appliance comes in an IP40 standard fanless design and can operate across -40°C To 70°C temperatures.

How can the EAI-I130 empower AMRs?

The EAI-I130 can empower AMRs at a large-scale warehouse by providing an onboard AI inference system and allowing the AMR to operate on a private 5G edge network.

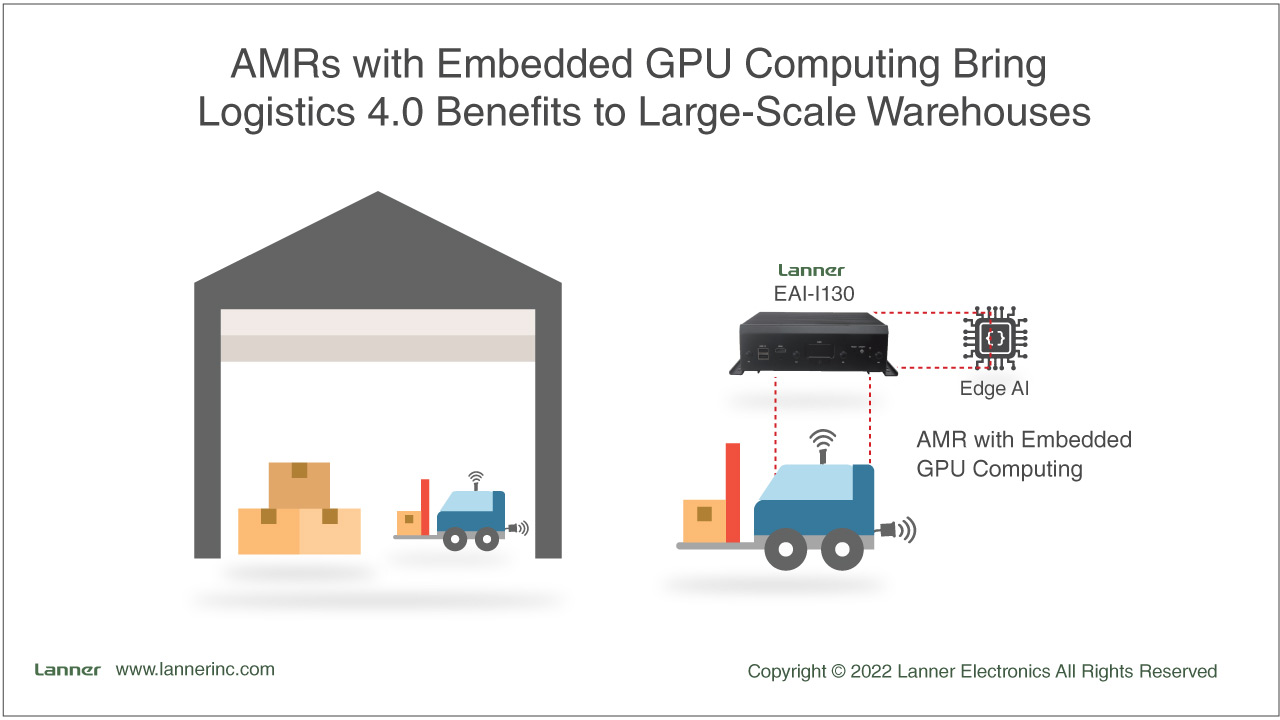

Below is a diagram of how the AMR with embedded GPU computing operates with the EAI-I130. The AMR relies on its built-in sensors to collect data from the external environment. This data feeds into the edge AI appliance (EAI-I130), which processes it onbard. In addition, with a private wireless network (Wifi6, 4G, or 5G), the AMR can also send data to the cloud or a high-end server for further analysis, storage, or remote monitoring.

Benefits

The main benefit of an edge AI solution for the AMR is that it brings the proper computing performance closer to where data is generated— to where sensors are located (in the Autonomous Mobile Robot). An edge AI computing platform like Lanner’s EAI-I130 allows AI to run directly on the AMRs, without having data leaving the warehouse floor. Running AI on the AMR can immediately enable real-time processing, lowers the need for bandwidth, and strengths security.

The EAI-I130 appliance processes collected field data and runs the necessary deep learning algorithms to help the ARM navigate and learn. In addition, the collected data can also help predict future demand, gain insights, or improve current processes. All benefits will ultimately generate new sources of revenue and save additional costs.

AMRs with embedded GPU computing bring logistics 4.0 benefits to large-scale warehouses, including:

- Improve data collection methods. Bringing AI-powered AMRs to the warehouses can help provide more precise data collection. AMRs can carry data-collection IoT sensors and cameras that capture internal or external factors from the warehouse, suppliers, carriers, or even customers.

- Increase AMR’s efficiency and safety. AMRs-powered by AI can perform the traditional ‘expected’ tasks like moving orders or sorting them. In addition, UAVs (Unmanned Aerial Vehicles or drones) with AMRs architecture can also be used for tasks like inventory auditing, stock-taking, stock maintenance, security, and item search.

- Assist warehouse workers and improve their productivity. Autonomous technology removes much of the manual tasks at the warehouse, reducing costs, improving productivity, and enhancing workers’ safety. An AMR-powered by AI will ultimately make wiser and faster decisions that will eventually impact safety and productivity.

Next Steps.

For more information on the edge AI appliance or the AMR with embedded GPU computing for large-scale warehouses solution, please contact Lanner’s sales representative.